For more than ten years, Fraunhofer FEP has been involved in the processing of ultra-thin glass, especially in the handling …

The vehicles of the future will be automated and networked to drive autonomously in road traffic and to relieve the …

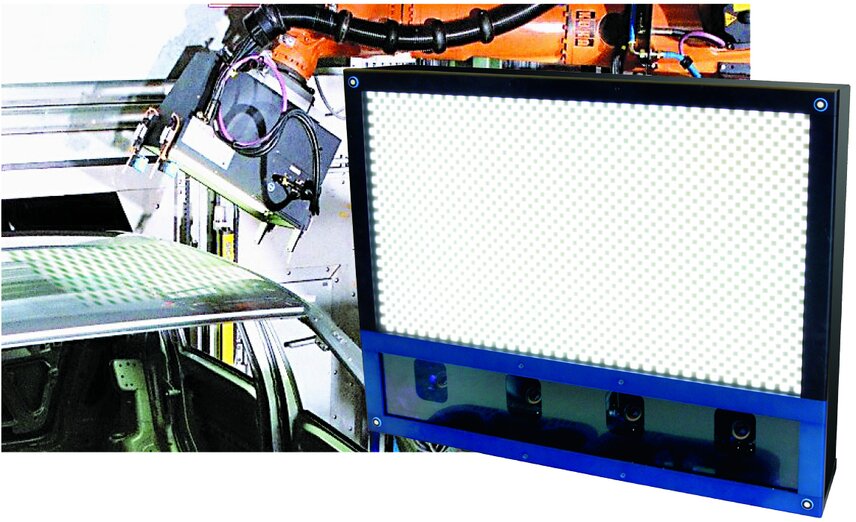

TRUMPF has developed laser technology solutions that enable the automotive industry to avoid chemical cleaning processes. In battery production, mini …