Favorite (4)

Favorite (4)

Semiconductors are materials with electrical conductivity somewhere between conductors (like metals) and insulators (like glass). This in-between behavior makes them perfect for controlling the flow of electricity – essential for building all kinds of electronic devices.

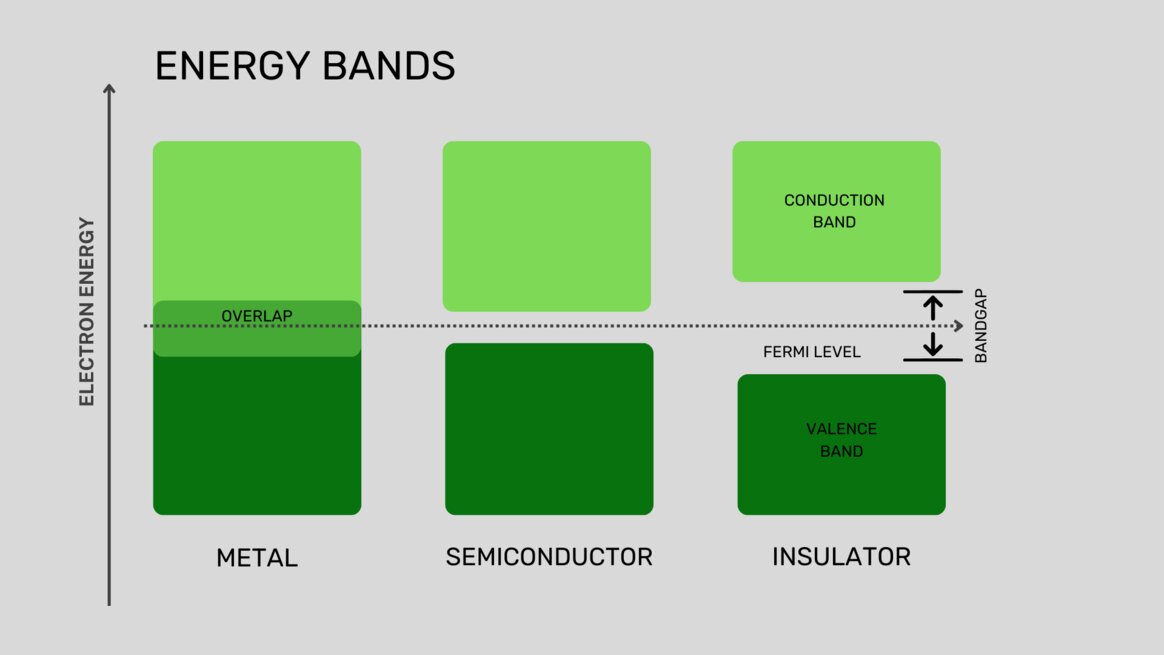

Their unique properties come from their atomic structure: in a pure semiconductor, electrons need just a small boost of energy (like heat or light) to jump from the "valence band" to the "conduction band" and start conducting current. By carefully adding impurities like other atoms – a process known as doping – engineers can tailor a semiconductor’s conductivity to fit specific applications.

You’ll find semiconductors in nearly every corner of modern life:

At absolute zero (0 K), semiconductors act like insulators. But at room temperature, electrons get enough energy to move into the conduction band and carry current. The trick lies in the band gap – the small energy difference that electrons must overcome. Materials like silicon and germanium have ideal band gaps for practical use. However, pure silicon is only a weak conductor of electricity at room temperature. But, its electrical conductivity can be greatly influenced by doping. Such dopants can be phosphorus or boron, for example. Semiconductors can then become:

When these types meet, they form p-n junctions – the core of diodes, transistors, and most other chips.

Semiconductors come in many flavors:

Fun fact: Silicon comes from sand. One ton of sand can produce about 3,000 wafers, each 300 mm in diameter!

Semiconductor manufacturing is a highly advanced, cleanroom-based process that takes months and involves hundreds of steps. It’s divided into:

Single crystals are grown from high-purity silicon and sawn into thin (< 1 mm) so called wafers. These are ground and polished to serve as a substrate for further processes.

On each wafer, multiple chip layers are built using:

These steps are repeated several times (over 100 times) to create complex layer structures with up to 15 levels – like a skyscraper made of atoms.

After testing, wafers are cut into individual dies, packaged, and wired up. Then, they’re ready to power your devices.

Watch how it works:

Some milestones:

1727 – First distinction between conductors and insulators (Stephen Gray)

1906 – First silicon diode patent (Pickard)

1947 – First transistor built at Bell Labs

1954 – First pure silicon via zone refining (Siemens)

1976 – First organic semiconductor (Heeger, MacDiarmid, Shirakawa)

The COVID-19 pandemic and recent geopolitical tensions revealed a painful truth: Europe relies heavily on Asian chipmakers. While the U.S. leads in chip design, most manufacturing happens in Taiwan (TSMC) and South Korea (Samsung). China is rapidly expanding, raising concerns over supply chain security.

Europe, currently holding less than 10% of global production, lacks advanced fabs below 7 nm. Yet it remains strong in areas like design of chips for power electronics, high-frequency and analog technology, sensors and microcontrollers - key components for the automotive and manufacturing industries. Europe is also a global center for semiconductor research. Leading research institutes and companies are driving technological innovation and miniaturization here.

To strengthen its position in the global semiconductor market, the EU introduced the European Chips Act. The goal: double Europe’s chip production share to 20% by 2030 and become a leader in next-generation microchips.

The initiative focuses on five main areas: boosting R&D, expanding capabilities in chip design and manufacturing, attracting cutting-edge fabs to Europe, addressing the skills shortage, and improving supply chain resilience.

At its core, the Chips Act aims to reduce Europe’s dependence on foreign technology and secure its role in a digital, connected, and sovereign future.

With over 1 trillion chips produced in 2020 alone, semiconductors are as critical as energy or water. No cars drive, no machines run, no phones connect without them. They are the strategic resource of the 21st century – essential for innovation, security, and sustainability.

Europe must invest, collaborate, and innovate to stay competitive. The opportunity is here: strong R&D, world-class suppliers, and industries that rely on smart microelectronics. With the right focus, Europe can build a digital future that is both powerful and sovereign.