Taisei Kogyo is one of the leading companies in Japan using Metal Injection Molding (MIM) technology. With MIM technology, the company builds the shape from powdered metal and binder injected in a mold, which is then sintered in a furnace leaving the sole metal as material behind.

The company’s strengths consist of serial production of high-precision small metal parts such as gears, screws and so on with a high complexity and free-form surface using MIM technology. Designs like that are not possible with conventional, mechanical technology. The components are made of various stainless steels, titanium alloys and other metals.

During Taisei Kogyo’s R&D work of over 20 years the company made progresses in miniaturization, higher accuracy and lower unit costs. Taisei Kogyo receives enquiries from industries such as medical equipment, precision equipment, and electrical and electric equipment, as well as optical instruments. Technical development of medical equipment parts is one of the areas Taisei Kogyo is focusing on. These high precision parts are often suitable for MIM technology.

Just in time for the 6

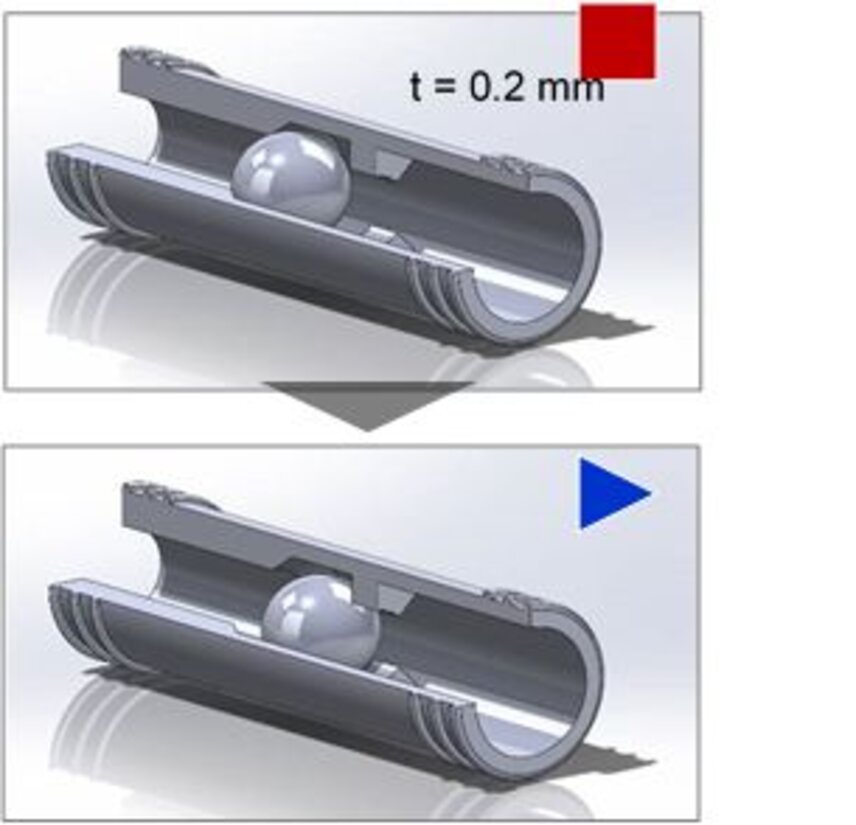

th Medical Equipment Exhibition (MEDIX) held in Tokyo, June 24-26, 2015, Taisei Kogyo has developed the smallest check valve made by MIM technology with the aim to reach a size as small as φ2.4mm, which was considered the limit of such check valve production by MIM technology. A check valve is a valve that normally allows liquids or gas to flow through it in only one direction. In some check valves a spherical ball is used to block or release the flow. These check valves have a wall thickness of 200μ.

This is a good example of the μ-MIM technology which also enables the company to build metal parts with a wall thickness of under 100μ and a special sacrificial inner mold. Taisei Kagyo is able to mass produce small parts like the check valve.

Taisei Kagyo will exhibit its products and technologies at this year’s COMPAMED in Düsseldorf in November 2015, which is part of the MEDICA exhibition. Furthermore, the company plans to set up an European representative office in Germany in near future.

Contact: Izumi Nakamura, Taisei Kogyo Co.,Ltd

izumi_nakamura@taisei-kogyo-net.co.jp